Constructing an accurate and quality frock coat is all about the details. One such detail is the buttons, often covered in fabric and which could take hours of work to complete. Cloth buttons were very commonly used on frock coats during the 1860s period. Of about one dozen original frock coats I have examined, all of them had cloth covered buttons, either in self fabric, or a matching silk.

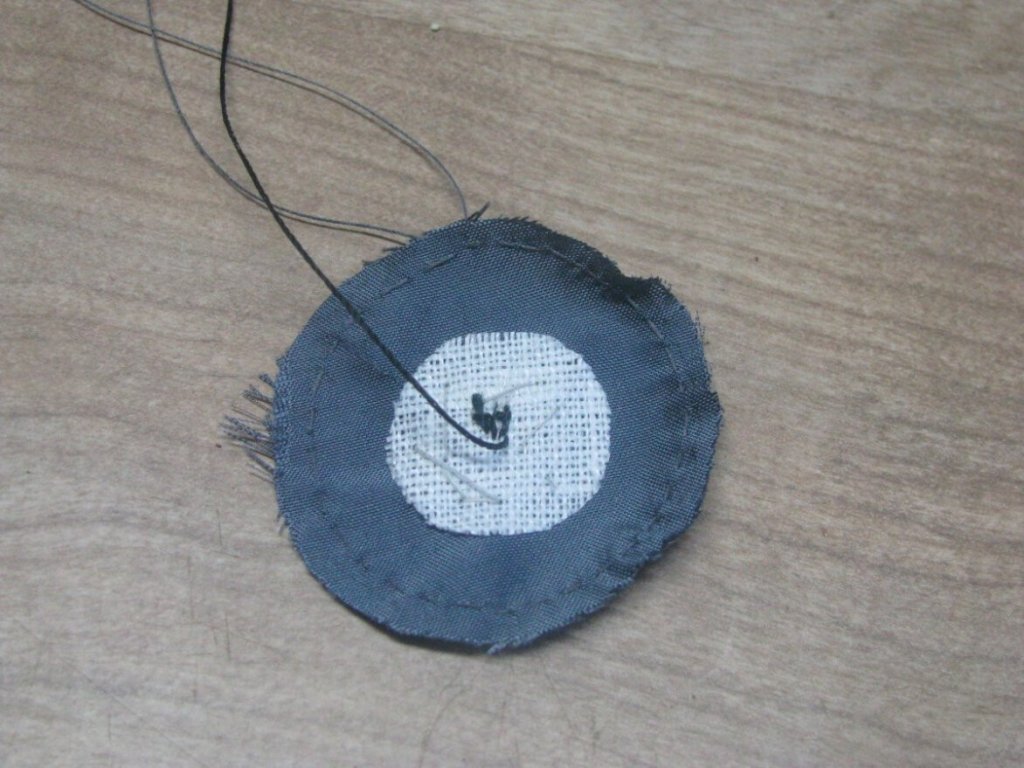

The first step is to determine the diameter of your button mold. Since they are curved on the top side, they therefore have more length there. Wrap your tape measure around the center of button mold, and divide the measurement in half. This gives you some additional room, since it accounts for the curvature of the mold.

Embroidery

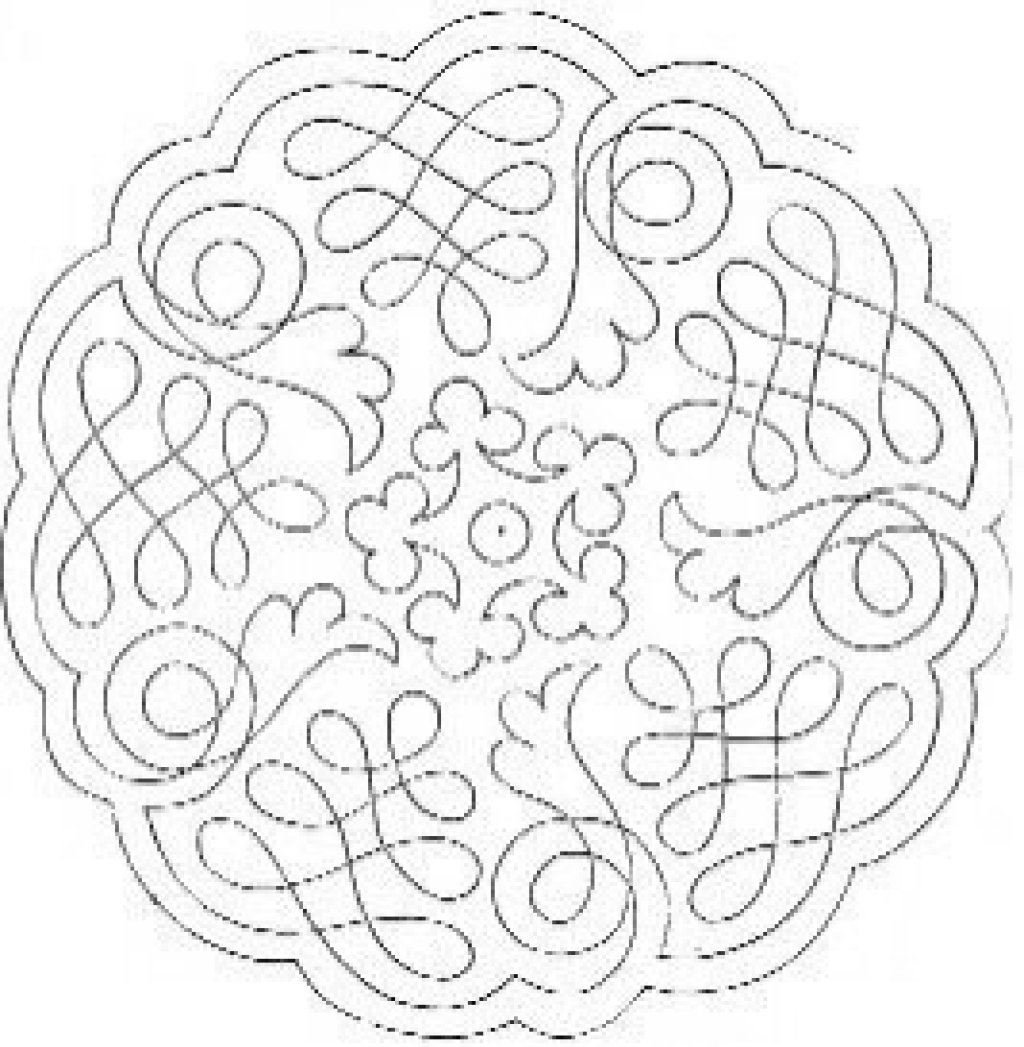

An additional feature present on some buttons were custom embroidery. Keep in mind this step is completely optional, and plain buttons were the most commonly used. This embroidery could range from simple geometric patterns, to initials, to more elaborate designs. While the embroidery itself is outside the scope of this workshop, I will go through the process that I used, so that you may have a place to begin your own research from.

Now that you have the diameter, it’s time to locate an appropriately sized pattern. With today’s computer technology, it is easy to scale patterns to the correct size, but you should find something approximately the correct size. I found an embroidery pattern in a Godey’s Magazine issue from 1860. The pattern was originally for a pincushion, but I noticed the middle was the perfect size for a button.

Taking that, I digitally cropped and attempted to clean up the pattern as best I could. Next, I placed it into an illustration program called Inkscape (free to download and use), and added the appropriate sized border around the pattern, using twice the diameter measurement. From there, the pattern was copied and spaced so that I could print it out to use as my pattern. Note that four were scaled down further, for the cuff buttons. I’ve included this pattern on the next page so that you’ll be able to see and follow the process in its entirety.

I placed this pattern under my silk taffeta, and outlined the pattern with a fabric safe pen over a light table. There are other ways to do this, such as special transfer paper that you can embroider over, tearing it away afterwards, and other methods, but this is what has worked for me. I encourage everyone to experiment on their own before committing to a method.

Finally, the buttons are ready for embroidery. This again is outside the scope of the course, but I’ve included the embroidery I had done by a friend as inspiration for you. The buttons are simply backstitched with silk embroidery floss, with a satin stitch in the middle.